Whether you need a custom encoder solution for your unique requirements or prefer a ready-to-use option from our current product range – Absolute Magnetics delivers the right solution for your application.

Every application has its own challenges — and we believe your encoder should fit them perfectly. Whether you want to optimize the compactness of your design or meet a specific technical requirement, we create solutions that adapt to your needs. Don’t make your design fit the encoder — integrate it seamlessly into your system with a tailor-made Absolute Magnetics Encoder.

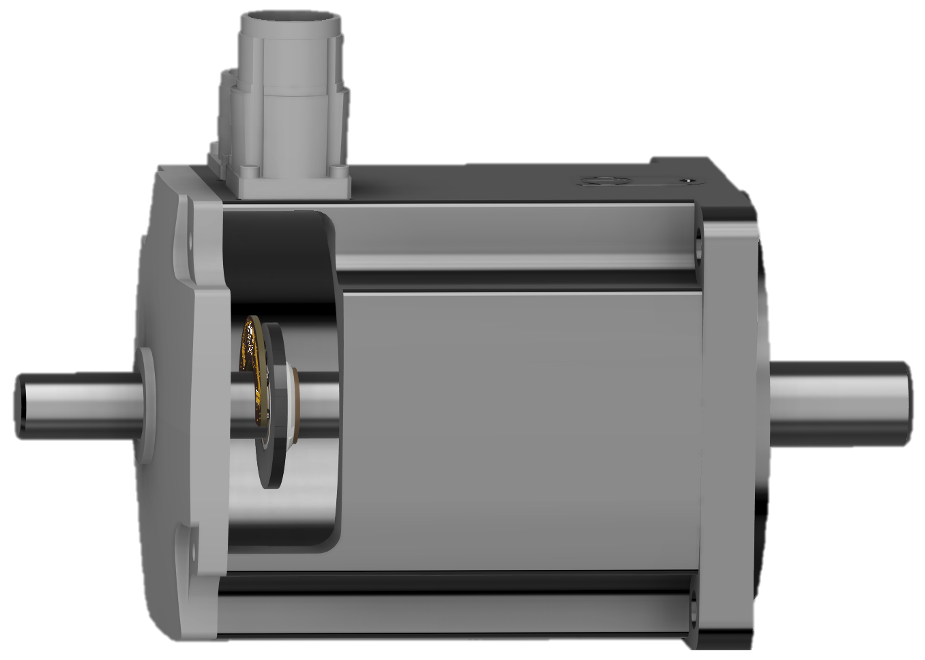

The AM Integrate Series is ready to be used in your application. The encoder does not need any kind of calibration – just power it on and get your precise absolute position. The encoder is extremely robust and can maintain reliable angle sensing despite air gap changes, mechanical misalignment and magnetic stray fields.

| Accuracy without calibration: | ±0.3° |

| Resolution: | 8 to 14 bit |

| Air gap: | 0.2 mm to 2.0 mm |

| Shaft diameter: | 15 mm |

| Operating temperature: | -40°C to +105°C |

| Speed: | 15’000 rpm |

| Output: | ABI, UVW, SPI |

The best way to understand a new technology is to experience it firsthand. That’s why we created the AM Evaluation Kit — a complete package designed to help you explore and evaluate our technology quickly and effectively.

The kit includes both the electronic module and precisely machined mechanical parts, providing everything you need for convenient testing and demonstration.

We are happy to develop integrated sensor kits in a tight collaboration with our customers. Let us know your specifications, either by filling out the form or by submitting your requirements via email: contact@absolute-magnetics.com

Here you’ll find answers to the most common questions about Absolute Magnetics Technology:

An absolute magnetic encoder is a sensor that measures angular or linear position using magnetic fields. Unlike incremental encoders, it assigns a unique digital code to each position, allowing it to retain accurate position data even after power loss. This makes it ideal for robotics, automation, and motor control systems requiring reliable, repeatable performance.

An absolute magnetic encoder works by detecting the orientation of a magnet relative to a sensing chip. The sensor measures magnetic field components and converts them into digital angle or position data. This data is transmitted through interfaces such as SSI, BiSS, or CANopen, ensuring precise, absolute feedback to your control system — even after shutdowns.

Absolute Magnetics AG has developed a multi-periodic magnetization technology that integrates several magnetic tracks into a single measurement pattern. This patented approach delivers accuracy, excellent tolerance to misalignment, and resistance to stray magnetic fields — all without needing complex calibration. The result is a compact, robust, and cost-efficient encoder suitable for demanding industrial applications.

Absolute Magnetics AG encoders deliver accuracy better than 0.5° in standard configurations and can achieve below 0.1° with calibration. Resolutions up to 16 or more bits per revolution are available, depending on the model. This combination of accuracy and robustness makes them ideal for high-precision motion control and industrial automation.